New Valve Family Opens Additional Application Possibilities

Cincinnati-based Clippard Instrument Laboratory created its EV line of valves in 1973. The company's workhorse pneumatic valves have seen a lot over their lifetime—video games like Pong have evolved into lifelike realty games and mobile phones the size of loaves of bread are now compact, thin devices that can do just about everything a computer can and more. And like the popular Energizer bunny, they have kept chugging along as the company introduced additions to the line Now, a generation later, the company is launching a companion series, the DV valve. The initial product is a high flow, 2-way bidirectional electronic valve, which offers flows to 100 lpm. Impressively, the valve has a life of more than 1 billion cycles. A robust stainless steel spider-style flat spring is used in the design.

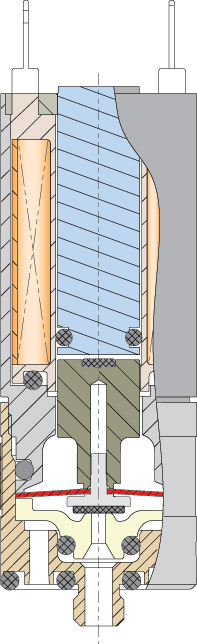

Clippard's new DV valve is available in manifold or cartridge styles, offering extremely high flow rates of 100 lpm at 100 psig.

The DV valve line features a robust stainless-steel spider that offers stronger and longer strokes than previous designs. The spider (center), is a plunger assembly with an overmolded seal and bumper The company has been quietly working on the design, and invited the Design World editorial sta! to its production facilities in Fairfield, Ohio, to see the design and witness the process of assembling the valves. According to Rob Clippard, the industrial marketplace has been asking for more flow from the EV valves for some time, and the new DV series will attempt to maximize power, flow and cost considerations versus competitive products. Applications for the DV include gas and liquid chromatography, gas sampling analyzers, oxygen wound therapy cuffs, ventilators, respirators, leak detection processes, as well as packaging and material handling. Like the EV valve—which was developed ahead of its time as a miniature option to provide low leak rates and long life—the DV valve, too, is going to be a unique product in the market. While some competitive valves may offer similar flows or power, none can offer the same power and flows for the price, said Clippard. High flows, low leakage The valve offers a 10-15 msec response rate and can be connected via spade terminals or wire leads. Featuring Ultem, PPS and stainless steel parts, as well as Nitrile standard sealing (FKM, silicone and EPDM are optional), the DV valve is rated for temperatures from 32° to 180° F (0° to 82° C). The stainless steel comes into play with the spider design, which features an over-molded seal. Although offered now in a 2-way version, a 3-way version is under development and McBreen said an isolation or proportional valve design would come next.

The DV valve's internal mechanisms ensure fast response and low heat rise and power, making it suitable for medical, analytical, and packaging applications. Manufacturing in America "We believe our people make our products great," said Campbell, who stressed that they consider themselves an American manufacturer and an engineering company first. "I think that pneumatics still has a very strong place in American manufacturing today," he said. |