Maximizing Precision & Flow Control While Reducing Heat Buildup in Chemical Analysis Systems

Imagine you’re designing an advanced chemical analysis system for a high-tech research lab. Your goal is to create a system that provides precise control over reagent flow, minimizes waste, ensures consistent performance, and guarantees high reliability throughout the process. This type of application demands a valve solution capable of precise mixing and controlling of reagents, while operating efficiently over extended periods without introducing variables that could compromise result accuracy.

After analyzing the demands of your application, you start evaluating your options. You need valves that can handle both gradient mixing and diverting applications, where accuracy in flow control is absolutely critical. They must also be able to withstand aggressive fluids, as your research involves a range of chemicals that could be corrosive or volatile. In addition, you want a valve that offers high cycle life, fast response time, and minimal dead volume to ensure consistency over time.

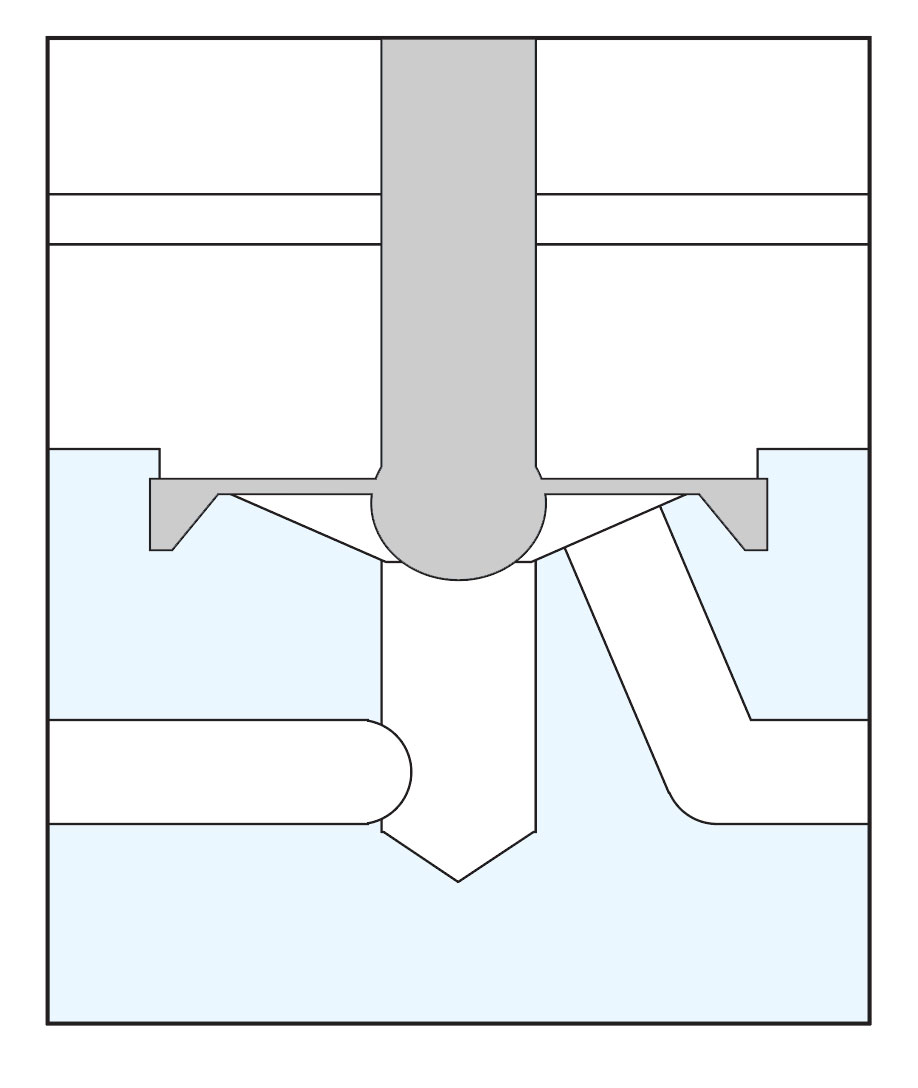

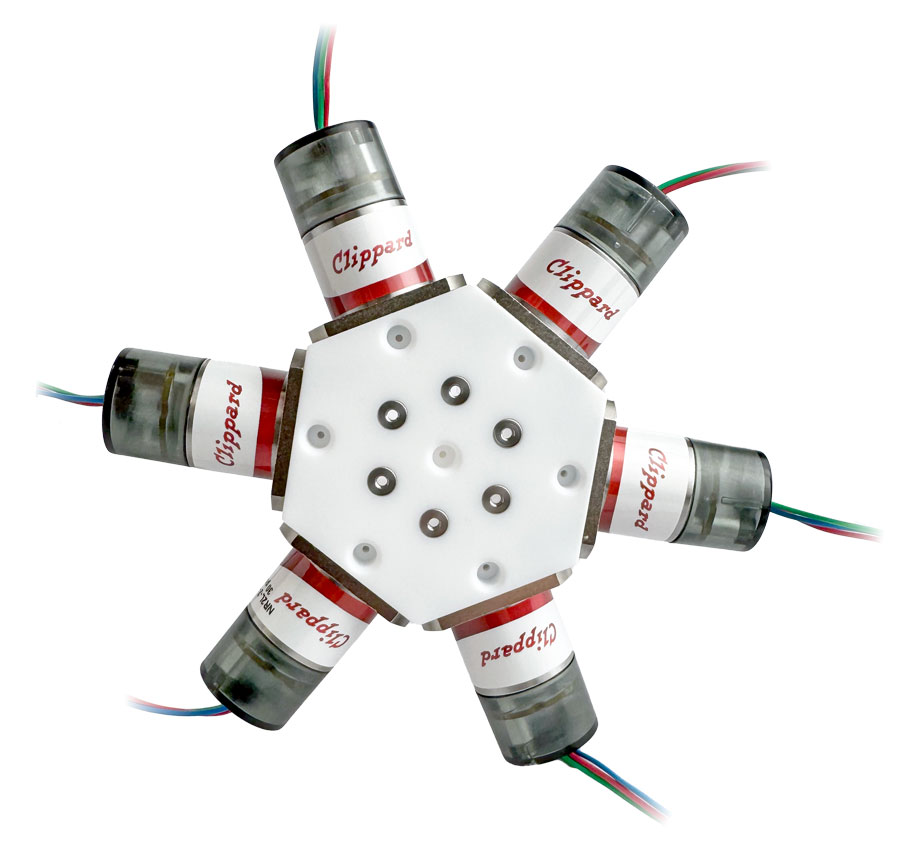

This is where Clippard’s NIV Gradient Mixing Valve comes into play. The NIV series is designed with a unique, multifunctional diaphragm/poppet that serves as both a sealing membrane and a support for the poppet. This results in fewer moving parts, reduced dead volume, and longer valve life—all essential for high-precision applications. Given the complexity of your needs, you need something that won’t introduce unnecessary components or cause reagent loss, which is why the minimal dead volume of the NIV Gradient Valve is a major selling point. It ensures accurate mixing, minimizes waste, and enhances the efficiency of your experiments.

Energy efficiency is also a critically important consideration for your system’s long-term operation. Since your system will be running continuously, you want to avoid excessive heat buildup, which could compromise both your research and the longevity of your equipment. Even a minuscule amount of heat buildup can affect the stability of the sensitive reagents you're working with, potentially altering their properties and undermining the reliability of your results.

Since Clippard’s isolation valves are designed with these concerns in mind, a Hit & Hold circuit is available as a standard option. This feature energizes the valve to full power for a brief moment, providing the necessary strength for precise operation, and then reduces the current to a lower, optimized level. This reduces the heat generated during continuous use, while still maintaining the exact control needed for your gradient mixing and reagent dispensing.

The Hit & Hold feature seamlessly integrates with the NIV Gradient Mixing Valve to optimize performance. It allows you to optimize both the energy consumption and thermal performance of your system without sacrificing precision or reliability. With reduced heat generation and lower power draw, your system can run efficiently over long periods, keeping your reagents at stable temperatures and preventing unwanted fluctuations in your results.

If your application requires precise flow control, minimal reagent waste, durability, and efficiency, Clippard’s NIV Gradient Mixing Valve with the Hit & Hold option is a reliable, high-performance solution. This combination addresses the critical challenges of this type of application, creating a reliable and long-lasting chemical analysis system. It ensures that your system will maintain peak performance over time, all while keeping power consumption low, reducing heat buildup, and extending the life of your valves.

Ready to learn more? Contact us today to discuss your specific application, or click here to locate your nearest Clippard distributor.