The Importance of Zero Dead Volume Fittings

Just as a chain is only as strong as its weakest link, a valve or system’s quality of operation is only as good as its connections—specifically, its fittings. This article will discuss what zero dead volume fittings are, explain why they are important, and provide specific examples of how they are used with two of Clippard’s precision isolation valves.

What are ZDV fittings?

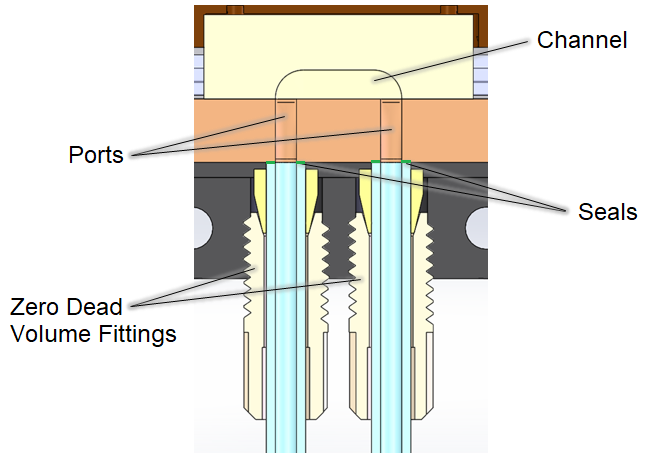

Dead volume is any space in the flow path that is not cleanly swept by the media’s laminar flow. Figure 1 (below, left) shows a cross section of a valve secured to a manifold. The media must flow from the valve, through the manifold, and into a fitting. The zone highlighted in red shows the dead volume. This is an extreme case and would not be used in applications where dead volumes severely reduce the quality of a system’s function. However, it demonstrates how hardware and channels drilled into manifolds add to the total volume a fluid must traverse, and how the fluid may not be able to cleanly sweep through.

Figure 1: Valve secured to a manifold with standard fitting |

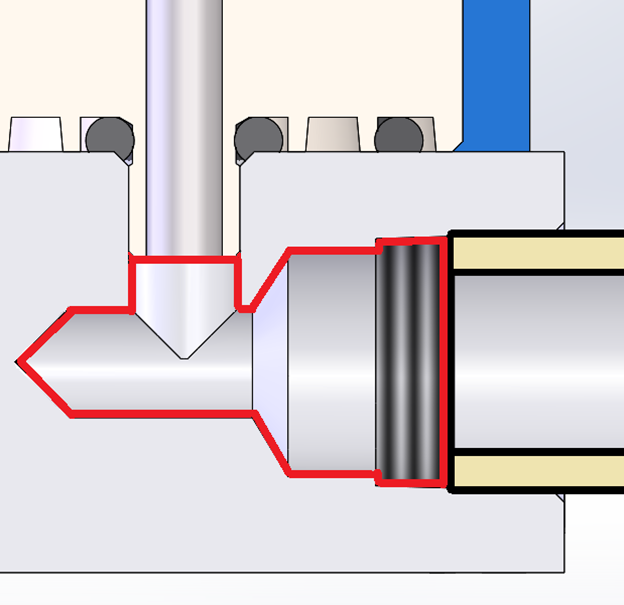

Figure 2: Example of a zero dead volume fitting |

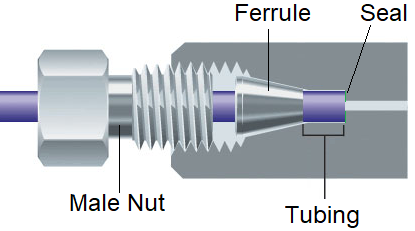

Zero dead volume (ZDV) fittings are special fittings which eliminate dead volume by ensuring the outlet seals right against the inlet that takes the medium out of the immediate system (or vice versa). These types of fittings typically include a nut and a ferrule that is inserted into a specially drilled hole. When correctly installed, the nut and ferrule allow the gripped tubing to seal directly onto the outlet surface, causing little to no disruption in laminar flow (Figure 2, above). Notice there is no gap between the tubing and the inlet’s surface where it must seal and that the tubing is flush against the surface. If there was a gap, a seal would not be guaranteed and the system would have added dead volume.

Why are ZDV fittings important?

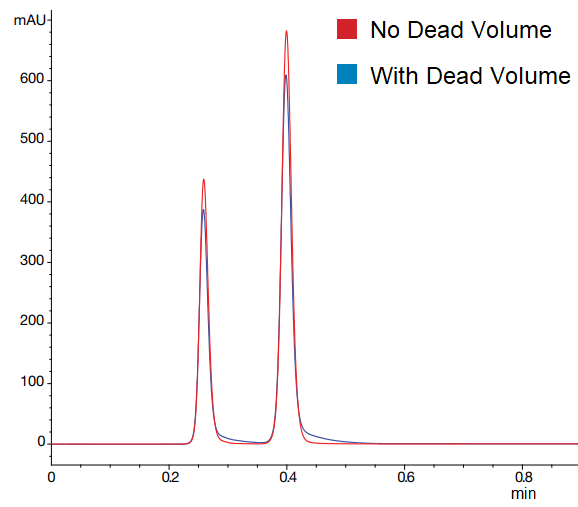

Figure 3: Results with and without ZDV fittings

(Source: Chromservis)

Dead volume can lower the overall efficiency of a system by reducing response time and causing diffusion of the media (due to the disruption caused to flow). For certain applications, such as chromatography, dead volume is a great enemy that can skew results and even cause method transfers or system suitability testing to fail because it leads to too much diffusion (Figure 3, right). Limiting or eliminating dead volume is especially important in applications using expensive solvents or compounds that must go through the system. The smaller and more streamlined the internal volume, the better.

Just how critical a zero dead volume fitting is will depend on the specific requirements of the application. Is it important to use as little media as possible? Is cleanliness a priority? Does the system need to be fully flushable? Is the media sensitive to disturbances in the flow, i.e. diffusion? Is limiting dead volume imperative to getting reliable results? If the answer to any of these questions is yes, the application may benefit from a zero dead volume fitting.

Selecting an Appropriate ZDV Fitting

From stainless steel to plastic, there are hundreds of different types of fittings that can be used. Selecting the most appropriate fitting requires not just knowing what type of connector or fitting is needed, but also understanding various other aspects such as the size of the head of the fitting, the seal material, potential chemical compatibility issues, valve ports, depth of port, the maximum depth of the port’s threading, etc. However, when using a ZDV fitting in combination with a precision valve, the manufacturer of the valve should be able to recommend an appropriate fitting to help ensure maximum valve performance.

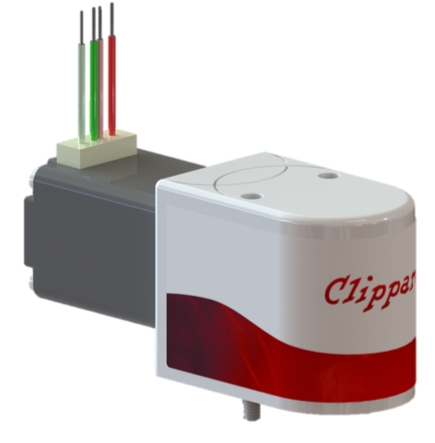

Clippard has two high-precision isolation valves that warrant the use of zero dead volume fittings—the NIV series all-PTFE isolation valve, and the Eclipse proportional isolation valve. Both of these valves were designed to have the least amount of internal volume and minimal dead volume.

ZDV Fittings for Clippard NIV Series PTFE Isolation Valves

Clippard NIV series isolation valve ports are designed for flat-bottomed flanged or flangeless fitting. These are typically two- or three-piece fittings which are often referred to as compression fittings. On some low pressure valves, a barb style fitting may be used that would have the same features as the compression fitting by sealing on the bottom of the port. The flat bottom port enables the flange or ferrule to come in direct contact with the orifice of the valve, thereby eliminating any dead volume. This type of fitting is commonly used throughout the industry and is available from companies such as:

ZDV Fittings for Clippard Eclipse Proportional Isolation Valves

The zero dead volume configurations (EIVU-Z, EIVU-Z-ENS) of the Eclipse valve use two zero dead volume fittings, each a nut ferrule combination that is a flangeless 1/4-28 flat-bottom fitting for 1/8" OD tubing. This fitting seals the tubing up against the underside of the ceramic that has an inlet and an outlet beneath a sliding channel that tightly controls flow (Figure 4, right). The recommended tubing for the Eclipse is Tefzel (ETFE) tubing, 1/8" OD x 1/16" ID. It is important that the tubing is stiff to allow the ferrule to grip it without causing it to collapse.

Zero dead volume fittings (ZDV) are not always required, but they make a measureable difference when a system needs to be fully flushable or when dead volume is a severe detriment to its operations. For more information on internal volume and flushability, see Critical Aspects of a Valve's Internal Design.

By Jess Koeniguer • Design Engineer • Clippard

|

Related Products |

||||

|

Eclipse Proportional Isolation Valve  |

NIV Series PTFE Isolation Valve |

Zero Dead Volume Fittings |

||

Related Content