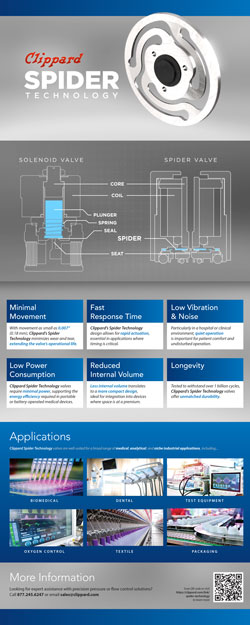

Clippard's Spider Technology

In 1973, Clippard patented a new valve design that utilized a unique sealing mechanism to improve performance and reliability. The design was a significant advancement and helped establish Clippard as a leading innovator in the field of pneumatic control. It featured a seal that was held in place by a very special spring, which consisted of a central plunger surrounded by several magnetically-responsive “legs” that moved in response to changes in pressure. When the valve was actuated, the legs moved outward, creating an opening that enabled media to flow through. It became known as the Clippard “spider.”

This technology has since been copied and mimicked by other manufacturers, but none have come close to perfecting it. Today, Clippard’s EV series—the original “spider” valve—remains the industry standard for long life and low leak. Building on this legacy, Clippard offers a wide range of valves that utilize this tried-and-true spider technology to meet the needs of many different industries and applications. All Clippard spider valves are extremely low leak. They provide exceptional reliability; long lifespans; and fast, precise control. They also consume very little power and have minimal internal volume.

Spider Valves Compared to Solenoid Valves

• Longer life—1,000,000,000+ cycles

• Lower vibration and noise

• Lower power

• Faster response time

• More compact and lightweight

• Less internal volume

• Better leak resistance

Benefits of Spider Technology

• Minimal Movement

With movement as small as 0.007" (0.18 mm), Clippard's Spider

Technology minimizes wear and tear, extending the valve's operational life.

• Fast Response Time

Clippard's Spider Technology design allows for rapid actuation,

essential in applications where timing is critical.

• Low Vibration and Noise

Particularly in a hospital or critical environment, quiet operation

is important for patient comfort and undisturbed operation.

• Low Power Consumption

Clippard's Spider Technology valves require minimal power, supporting the

energy efficiency required in portable or battery-operated medical devices.

• Reduced Internal Volume

Less internal volume translates to a more compact design,

ideal for integration into devices where space is at a premium.

• Longevity

Tested to withstand over 1 billion cycles, Clippard's Spider Technology

valves offer unmatched durability.

Spider valves are well-suited for a broad range of medical, analytical, and niche industrial applications including biomedical, dental, test equipment, oxygen control, textile, packaging, pressure control, automation and portable systems. Ready to learn more about how your application might benefit from Clippard's Spider Technology? Contact us today to discuss your specific application requirements.

Related Content

- Precision and Reliability in Critical Medical Applications

- Optimizing Packaging and Automation Systems with Spider Technology

|

Related Products |

||||

|

|

||||

|

|

||||

|

|

||||