Enhancing Air Compressor Efficiency with Pneumatic Valves

Air compressors are vital in many industrial applications, and achieving optimal performance involves more than just selecting the right components. Quality pneumatic valves, including check valves and shuttle valves, play an important role in enhancing system efficiency and reliability. Proper understanding and application of these components can greatly improve compressor performance, reduce operational costs, and extend equipment life.

Ensure System Integrity with Check Valves

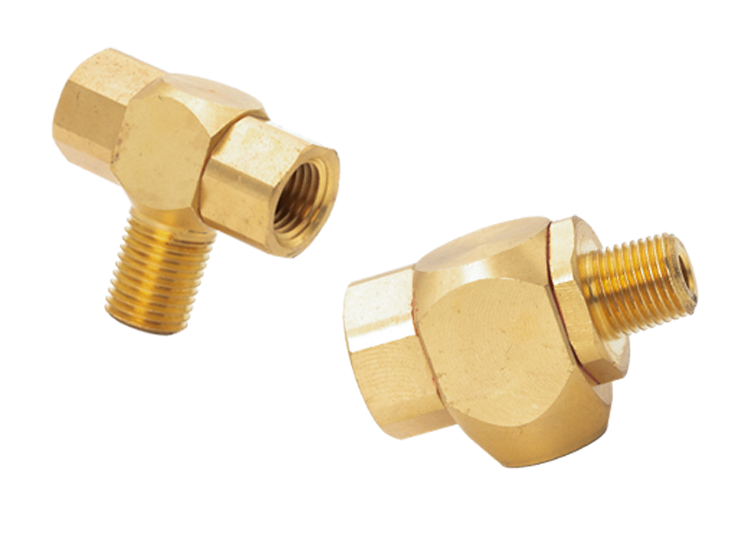

Check valves are engineered to allow air flow in only one direction, crucial for preventing backflow from the tank to the compressor head. This one-way flow is vital for maintaining system protection and efficiency. By preventing reverse flow, check valves shield the compressor from potential damage such as internal scoring or contamination, which can occur if air flow backs into the system. This protection helps sustain optimal system pressure and avoids costly repairs. Additionally, by eliminating backflow, check valves reduce the compressor’s workload, which can lead to significant energy saving and extend the equipment’s operational lifespan.

Proper selection and placement of check valves is essential—they should be carefully chosen to match the pressure rating and flow requirements of the specific compressor system. For optimal performance, check valves should be installed in the compressor discharge line, where they can most effectively prevent backflow. Positioning them too close to the compressor or in areas with high vibration can lead to performance issues and reduced valve lifespan.

Manage Multiple Air Sources with Shuttle Valves

Shuttle valves manage the flow between two alternate air sources, switching automatically based on operational status or pressure levels. Their primary benefits include seamless automatic switching, redundancy, and enhanced reliability. For instance, in facilities equipped with multiple compressors, shuttle valves ensure uninterrupted air supply by transitioning to a backup compressor if the primary one fails. This automatic switching minimizes downtime and maintains a constant air supply, which is essential in high-demand environments like manufacturing lines.

To ensure effective operation, shuttle valves must be compatible with the compressor setup and capable of handling the specific pressure and flow rates required. It is also good practice to regularly inspect shuttle valves to verify their functionality. Common issues, such as slow or unreliable switching, should be addressed promptly to avoid disruptions in system performance.

Optimize Air Compressor Performance with Pneumatic Valves

Pneumatic valves, including check valves and shuttle valves, are essential for maintaining consistent pressure and ensuring the efficiency, reliability, and longevity of air compressor systems. Contact Clippard or your local distributor for assistance selecting and maintaining pneumatic valves for your compressor system.

|

Related Products |

||||

Check Valves |

Shuttle Valves |

|||