Optimizing Pneumatic Control Systems with Injection-Molded Manifolds

Injection-molded manifolds can help solve some of the challenges industrial OEMs struggle with, including maintenance issues and energy inefficiencies that contribute to unnecessary downtime and high operational costs.

Problem:

Maintenance issues, downtime, energy inefficiencies, and increasing operational costs.

Industrial OEMs often face challenges when it comes to optimizing their pneumatic control systems. These systems are critical for maintaining precision and efficiency in a wide range of industrial applications, from material handling to assembly operations. Frequent maintenance issues, energy inefficiencies, and inconsistent performance can contribute to higher operational costs and unplanned downtime, disrupting production schedules and reducing overall productivity.

OEMs require solutions that are not only reliable and efficient but also scalable and cost-effective. The pneumatic control systems must integrate seamlessly into existing machinery, often within space and weight constraints imposed by the specific industrial environment. Additionally, there is a growing need to reduce energy consumption and enhance sustainability across operations, adding complexity to the challenge.

.............................................................................

Solution:

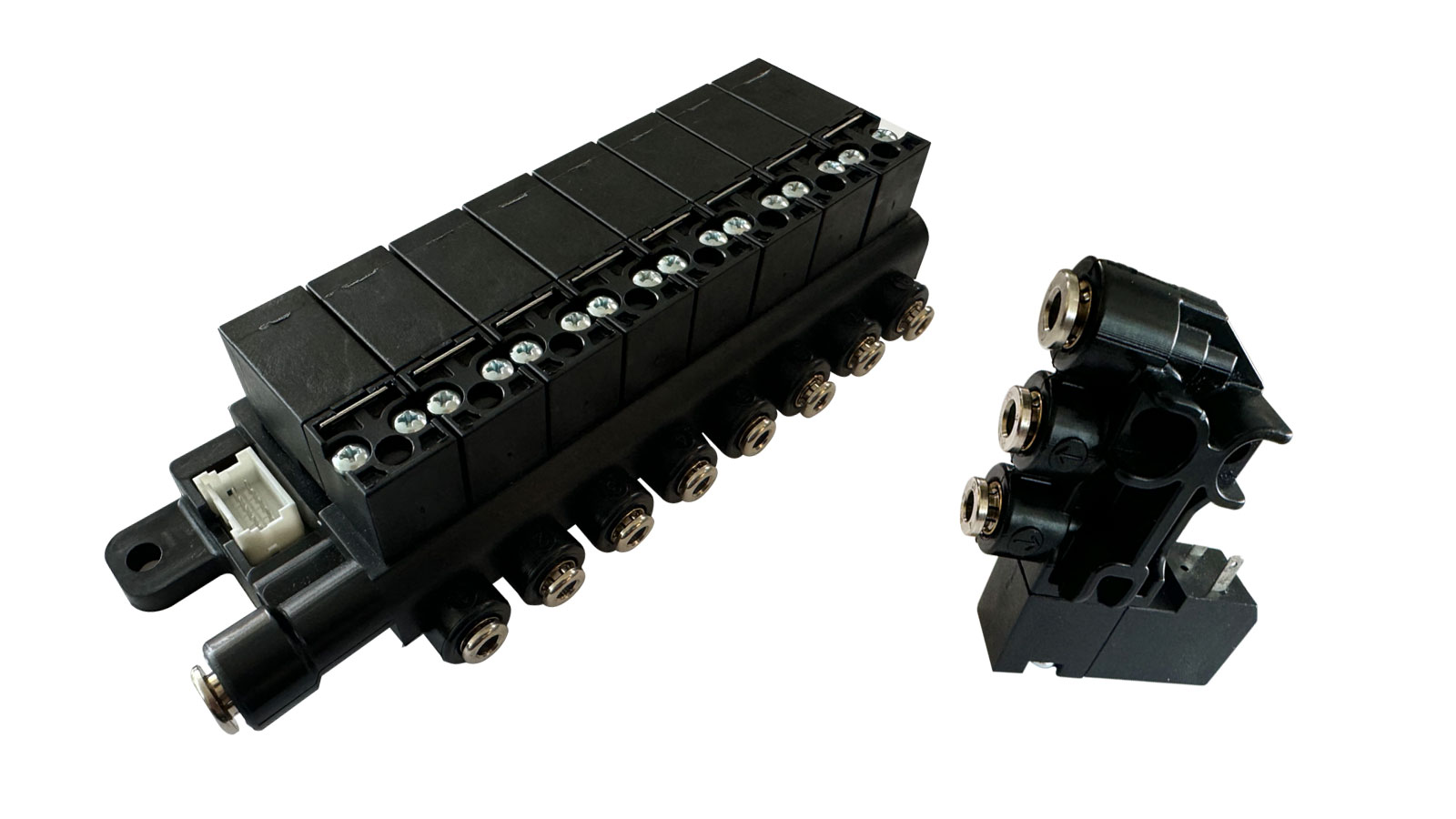

Special Clippard valve banks with injection-molded manifolds

One way Clippard is able to address these challenges is by upgrading the pneumatic control systems with compact, lightweight banks of valves on injection-molded manifolds. These three-way, two-position valves are selected for their versatility, reliability, and efficient air flow control, making them suitable for a wide range of industrial applications. They offer precise control over pneumatic actuators, minimizing air leakage and reducing energy consumption throughout the system. This not only results in significant energy savings but also improves the overall performance and reliability of the machinery, reducing the need for frequent maintenance and increasing uptime.

Injection-molded manifolds feature a lightweight and compact design that fits easily within the space constraints typical of many industrial environments. Its modular construction allows for easy scalability, enabling OEMs to implement the solution across a variety of machines and production lines with minimal modifications.

Furthermore, the cost-effectiveness of the injection-molded manifold and valves ensures that the solution meets budgetary requirements, making it ideal for large-scale deployment across multiple facilities. The outcome is a highly efficient, reliable, and scalable pneumatic control system that addresses the immediate needs of industrial OEMs while supporting long-term energy savings and sustainability goals.

Clippard's solution offers industrial OEMs a tailored approach to overcoming common pneumatic control challenges, delivering enhanced performance, reduced energy consumption, and improved operational efficiency across diverse production environments.

|

Related Products |

||||

Special Valve Bank with Injection-Molded Manifold |

Special Valve Bank with Injection-Molded Manifold |

10 mm Electronic Valves |

15 mm Electronic Valves |

|