Gradient Valves: A Versatile Solution for Fluid Mixing & Dispensing

In fluid control systems, precision and reliability are essential. Gradient valves, also referred to as mixing valves or multi-stream vavles, are specialized devices designed to efficiently combine or divert multiple fluid streams. These valves offer a versatile solution for a broad range of medical, analytical, and industrial applications. This article outlines the function, design, and uses of gradient valves, with a particular focus on their role in mixing, stream splitting, and fluid dispensing systems.

What Is a Gradient Valve?

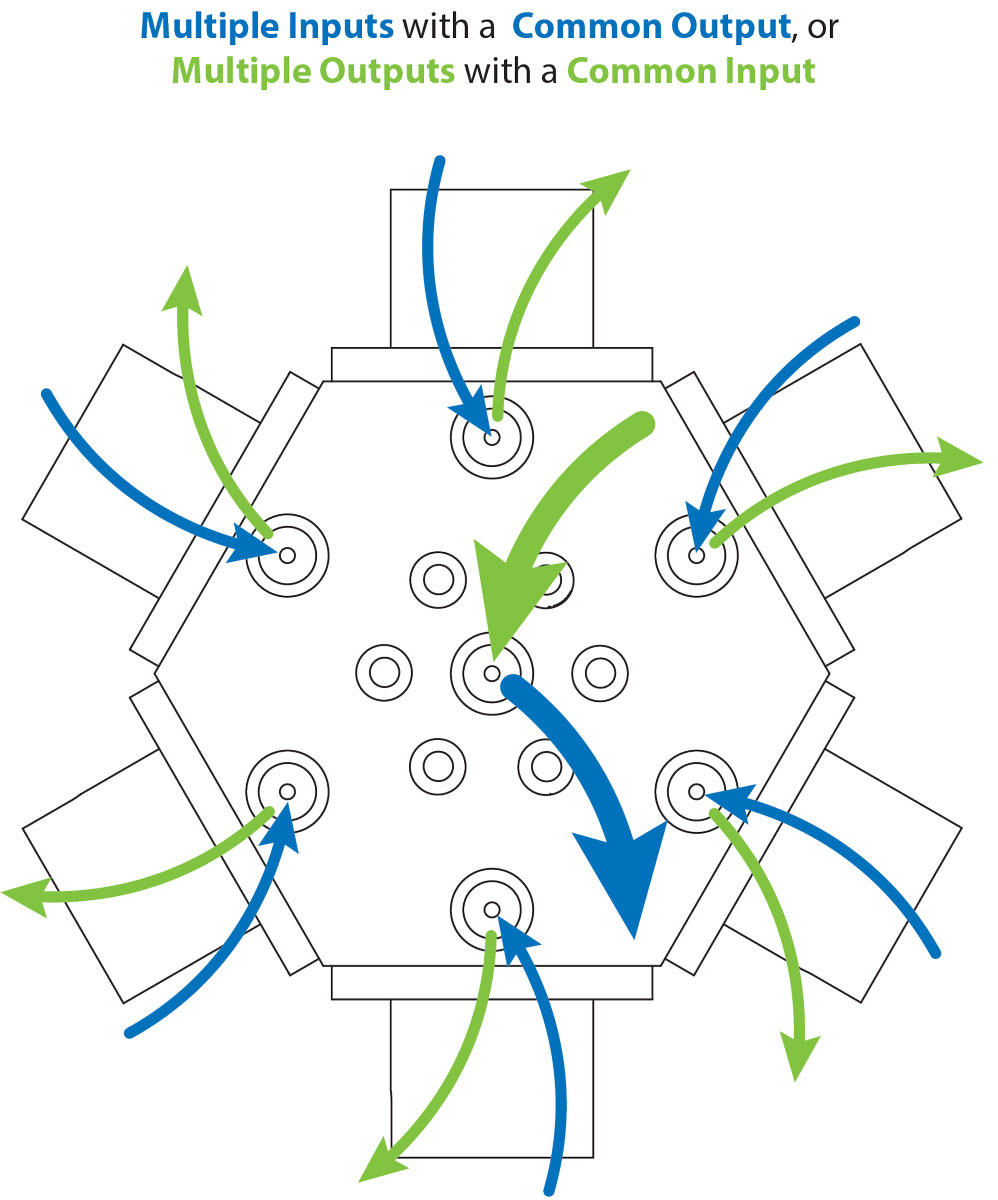

A gradient valve, or multi-stream valve is an advanced form of a mixing valve, designed to manage multiple fluid streams—either by combining them into a single flow or by diverting them to separate outputs. Unlike traditional valves that handle a single fluid stream, gradient valves allow for more complex fluid manipulation, making them ideal for applications that require precision mixing or fluid distribution.

Gradient valves are essentially a combination of multiple isolation valves, such as Clippard’s NIV series. By integrating these valves into a single manifold, gradient valves can efficiently mix various solutions into one output or distribute a single inlet to multiple outputs. This combination simplifies the design and operation of fluid handling systems, improving both performance and reliability while reducing system complexity.

Video filmed at Clippard in Cincinnati, Ohio

Subscribe to Clippard's YouTube channel

Design Variants: Selecting vs. Diverting Applications

Gradient valves are versatile in terms of design, with the ability to support both selecting and diverting applications. In a selecting application, the gradient valve is designed to combine multiple independent inlets into a single common outlet. This configuration is ideal for processes that require the mixing of various fluids into a unified stream. For instance, in chemical mixing or reagent blending systems, the gradient valve can accurately blend different substances to achieve the desired concentration or chemical composition. Diverting applications use a single common inlet and multiple independent outlets. This design is commonly used for stream splitting, where a single source is distributed to multiple destinations. This feature is invaluable in automated applications where one fluid source needs to be directed to several systems or stages of a process.

| Types | Design | Common Uses | Examples |

|---|---|---|---|

| Selecting Application | Multiple independent inlets combined into one common outlet | Processes that require mixing of various fluids into a unified stream | Chemical mixing or reagent blending systems |

| Diverting Application | Single common inlet with multiple independent outlets | Stream splitting where a single source is distributed to multiple destinations | Automated processes where one fluid source needs to be directed to several systems or stages of a process |

Applications of Gradient Valves

Gradient valves are crucial in a variety of industries, particularly those dealing with fluid control, chemical processing, pharmaceuticals, and automation systems. Some common applications include:

| Solvent Selection | Gradient valves can mix different solvents to achieve precise concentrations, ensuring optimal performance in sensitive industrial processes |

| Stream Splitting | In systems where fluid needs to be split across multiple channels for different processing stages, gradient valves provide a streamlined solution |

| Flushing Systems | Gradient valves allow for the controlled introduction of cleaning fluids in systems that require periodic flushing to maintain optimal performance |

| Automated Fluid Handling | Gradient valves enable automated processes by combining and dispensing fluids according to predefined requirements, improving efficiency and reducing human error |

Key Features of Gradient Valves

Clippard gradient valves consist of multiple solenoid-operated Clippard NIV series media isolation valves integrated within a single manifold. Each NIV valve features a unique flexible diaphragm that isolates the actuation mechanism from the fluid path, ensuring precise control over fluid flows without contamination. This design protects sensitive components from harsh media while enhancing the valve’s durability and longevity.

These gradient valves are particularly well-suited for industries handling aggressive or corrosive fluids. The fluid paths are made entirely of PTFE (Polytetrafluoroethylene), a material known for its exceptional chemical resistance, thermal stability, and low friction properties. This ensures Clippard gradient valves can withstand chemical reactions and handle a wide range of fluid types without compromising the integrity of the valve or system.

Clippard gradient valves are available in various sizes and configurations to meet the needs of different applications. Orifice sizes range from 1/32 to 0.156", enabling precise flow control. Additionally, these valves offer a range of power consumption options from 1 Watt to 7.2 Watts, allowing engineers to select the optimal valve based on their system’s flow and power requirements.

Benefits of Gradient Valves

Gradient valves, particularly those incorporating Clippard’s NIV series, offer several key advantages:

| Space Efficiency | Integrating multiple valves into a single manifold significantly reduces the space required for installation, which is especially beneficial in applications with limited space or when a high density of components is needed |

| Reduced Leak Points | By consolidating multiple valve functions into one unit, gradient valves minimize the number of connections and potential leak points, improving the safety and reliability of the system |

| Simplicity | Instead of dealing with multiple individual valves, engineers can use a single gradient valve to achieve multiple functions. This simplifies maintenance, reduces system complexity, and enhances operational efficiency |

| Durability | Clippard’s NIV series valves are designed for long-lasting performance, with features like a one-piece valve stem that centralizes the poppet and seals the diaphragm, resulting in fewer parts, reduced dead volume, and improved valve life |

Gradient valves are essential components in fluid control systems that require the handling, mixing, or diverting of multiple fluid streams. Their ability to manage complex fluid routing tasks with precision makes them invaluable across a wide range of applications, particularly those involving corrosive, sensitive, or aggressive media. Clippard’s gradient valves, which integrate multiple NIV series media isolation valves into a single manifold, offer unique advantages such as increased durability, space efficiency, and reduced leak points.

Whether used for solvent selection, stream splitting, or automated fluid handling, multi-stream mixing valves provide engineers with a reliable and efficient solution for optimizing fluid control systems. The integration of Clippard’s NIV series ensures long-lasting performance, making these gradient valves an ideal choice for applications where precision, reliability, and chemical compatibility are critical.

|

Related Products |

||||

Gradient Mixing Valves |

Media Isolation Valves |

|||