Special Materials for Demanding Applications

Understanding the best seal material for your application is imperative. Common factors that may need to be evaluated include chemical compatibility, extreme temperatures, cleaning requirements, or sometimes even restrictions on material outgassing. Many valves are offered standard with either nitrile or FKM seals. Yet, between these, how do you know which is the right choice for your application? What if neither of these materials meet your requirements? Clippard offers a wide selection of materials to meet the needs of many different types of demanding applications.

Chemical Compatibility

The most common reason to change materials in a valve is chemical compatibility. For example, a valve controlling the flow of acetone will have a short life if equipped with standard nitrile seals. In this case, selecting a different seal material that is more compatible with acetone will greatly extend the life of the valve. By referring to the Chemical Compatibility Chart we can see that for use with acetone, EPDM is the recommended material.

Temperature

Some applications expose valves to extreme temperatures. In these situations, it is important that the seal materials can withstand the environments they will be exposed to. For example, a valve that needs to be autoclaved for cleaning may be exposed to temperatures as high as 300°F. This extreme heat can damage standard nitrile seals, but this is easily avoided by selecting a material compatible with higher temperatures. By referring to the Material Properties Chart we can see that there are a variety of other seal materials to choose from which can handle temperatures reaching 300°F.

Special Media

Depending on the application, the media being passed through the valve may sometimes necessitate other special requirements. For example, applications involving corrosive fluids place greater demand on all wetted areas of the valve. In this case, a media isolation valve often provides the ideal solution. Clippard's line of PTFE media isolation valves are designed such that PTFE is the only wetted material, making them well-suited for these types of applications.

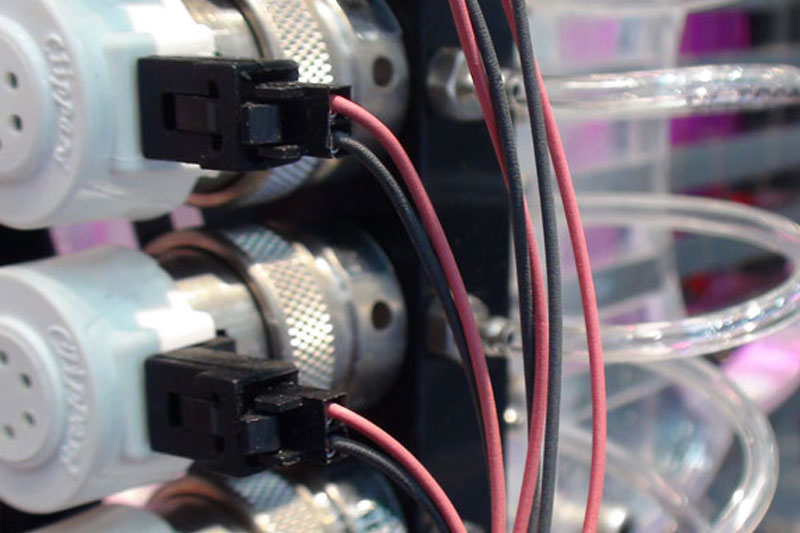

In other situations, applications may involve media with large particulates, or media that is especially sensitive to contamination. In these cases, a pinch valve often provides the ideal solution. Clippard offers both pneumatic and electronic pinch valves with a variety of different types of tubing including medical/laboratory grade silicone, FDA-approved food grade silicone, and polyurethane. The tubing is disposable and easy to replace, providing cleanliness, convenience, and a completely unobstructed flow path.

For help selecting the best materials for your application, call 877-245-6247 or contact your local distributor.

By Mike Kettering • Technical Sales Specialist • Clippard