When Cleanliness Matters, You Can Count on Clippard

It's no surprise that the cleaner your valve is, the less it will leak. However, cleanliness is also important in other ways, such as for medical applications where fluid flowing through the valves may be entering a person's body or for applications in the food and beverage industry. In these cases, the valves must not only be cleaned of any particulate matter, but also of any harmful substances used in the normal machining or assembly process. When cleanliness matters, you can count on Clippard to provide the special cleaning, assembly, and testing processes your demanding applications require.

Clean Rooms

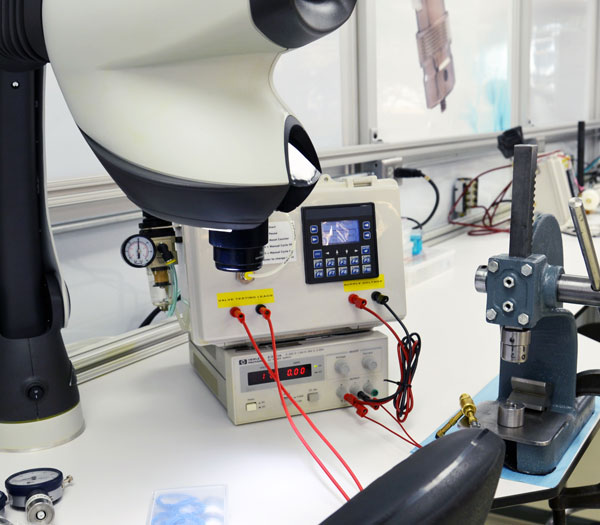

Each of Clippard's manufacturing facilities are equipped with custom isolation enclosures designed specifically for the pharmacy and biotech industries. These clean rooms provide enclosed, controlled environments for the assembly, inspection, and testing of sensitive valves and equipment. They help to protect against airborne contaminants, ultraviolet rays, and temperature fluctuations. Additionally, the modular nature of these enclosures allows Clippard to quickly and easily expand capacity to meet special requirements or increased demand.

Cleaning Capabilities

In addition to our clean rooms, Clippard has invested heavily in cleaning, inspection, and testing technologies for our valves. We have many options available upon request for special orders, such as:

- Ultrasonic cleaning of component parts

- Baking of seals in order to outgas chemicals

- Inspection of cleaned parts under ultraviolet light to detect oil or fibers

- Inspection of cleaned parts under microscopes

- Use of alternate lubricants/sealants or the exclusion of lubricants/sealants from the assembly process

- Testing using high purity compressed nitrogen in place of shop air

- Helium leak testing for ultra low leak requirements

- Packaging of cleaned parts in the clean room

- Double bagging of cleaned parts to ensure cleanliness

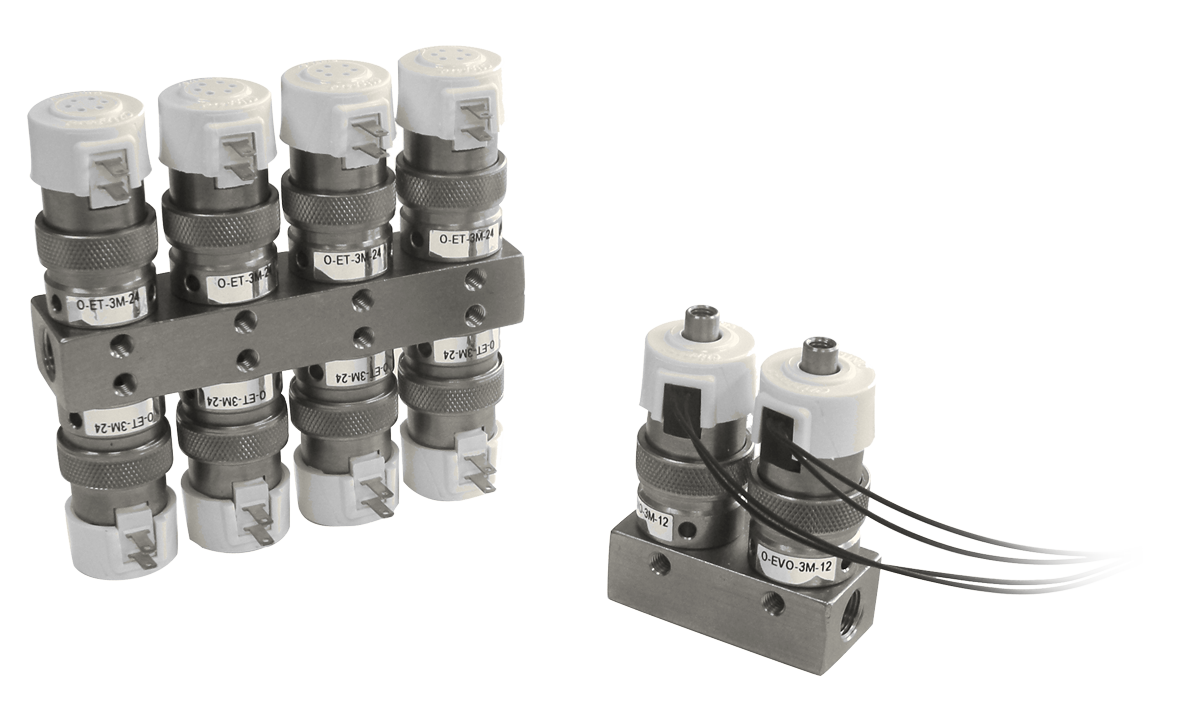

Cleaning Standards for Oxygen Service

Due to the high flammability of oxygen, parts used in oxygen-rich environments are extremely sensitive to contamination. Clippard has a number of Engineering Standards in place that dictate strict cleaning requirements for valves rated for oxygen-rich environments. This includes our standard "O-" series of electronic valves, but can also be applied to customer special orders upon request. Our cleaning standards for oxygen service include the following:

Download ES-3.41 Cleaning Specification (PDF)

- Valves are ultrasonically cleaned, assembled, inspected, and tested in a clean room area

- Cleaned parts are inspected under white and ultraviolet light to insure the absence of organic and inorganic contaminants, such as particulate and hydrocarbon contamination

- No organic sealants, adhesives, or lubricants are used in the manufacturing process

- Component parts are lubricated with oxygen-compatible PFPE (perfluoropolyether) grease, only as needed for assembly

- Valves are tested using high purity compressed nitrogen

- Finished valves are double bagged in heat sealed polyethylene bags

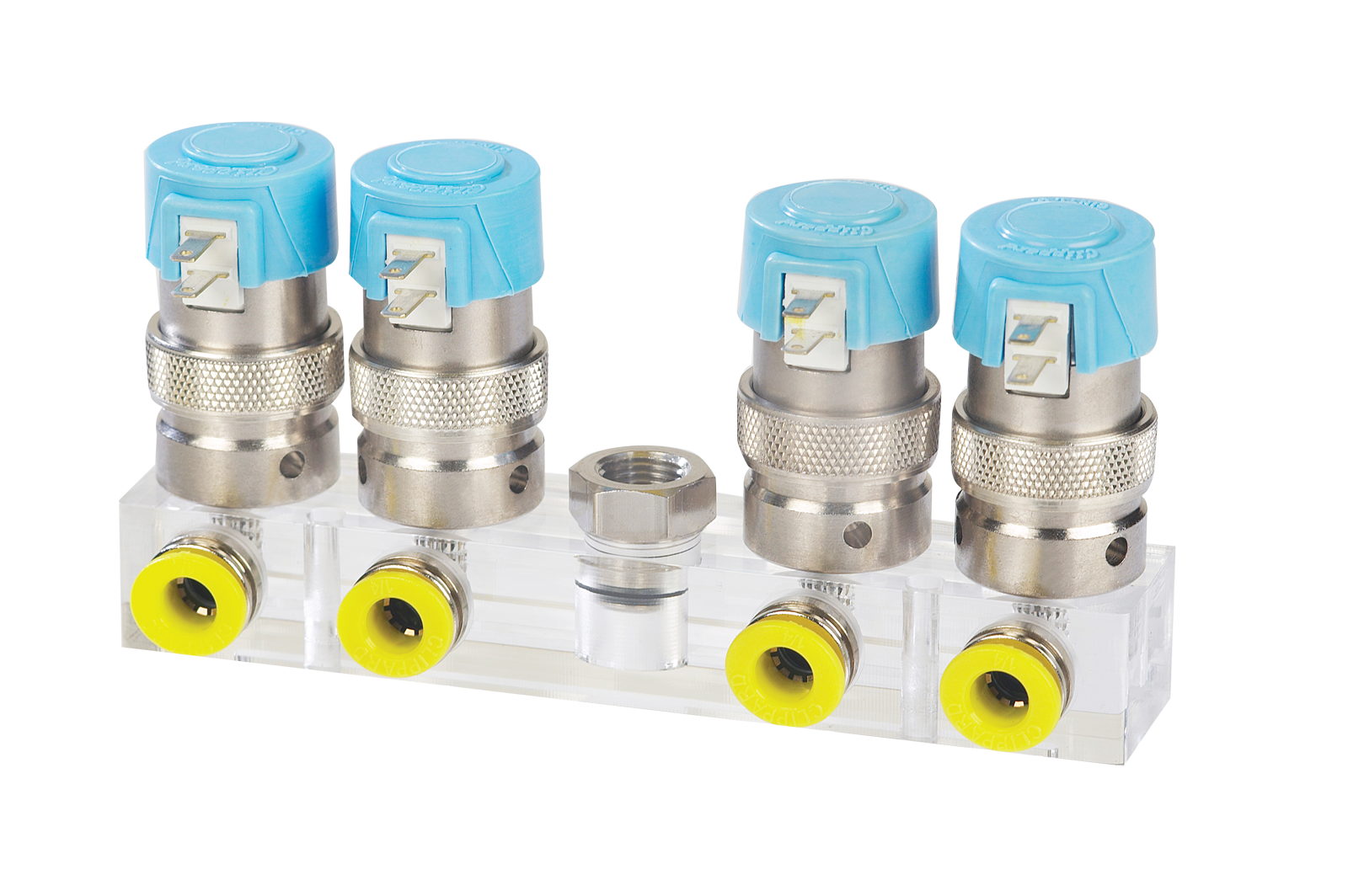

Cleaning Standards for Analytical Service

Valves intended for low-leak, high precision environments, such a laboratories, often require higher quality cleaning and handling to limit contamination. We created our "A-" series of electronic valves to provide a standard valve that meets these requirements. The assembly standards for these valves can also be applied to customer specials. Our cleaning standards for analytical service include the following:

Download ES-3.43 Cleaning Specification (PDF)

- Valves are designed with reduced leak paths

- Valves are ultrasonically cleaned, assembled, inspected, and tested in a clean room area

- Seals are cleaned ultrasonically with high purity alcohol, then heated to outgas before assembly

- Cleaned parts are inspected under white and ultraviolet light to insure the absence of particulate and hydrocarbon contamination

- Components are lubricated with isopropyl alcohol, only as needed for assembly

- Valves are tested using high purity compressed nitrogen

- Valves are pressure decay leak tested

- Finished valves are double bagged in heat sealed polyethylene bags

Special Cleaning Requirements

Do you have an application which requires special cleaning for its manufacture, assembly or testing? Contact Clippard today to discuss how we can meet your unique needs.