Pneumatic Solutions for Leak Testing

|

A leak is defined as an unintended passageway that enables fluid to escape plumbing, a component or a system. There are a number of methods used to detect leaks such as pressure decay, mass flow, bubble, sniffing and vacuum. |

|||

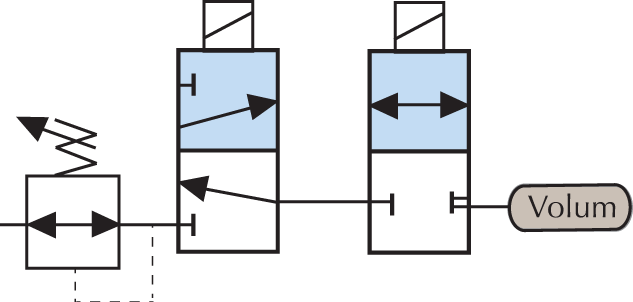

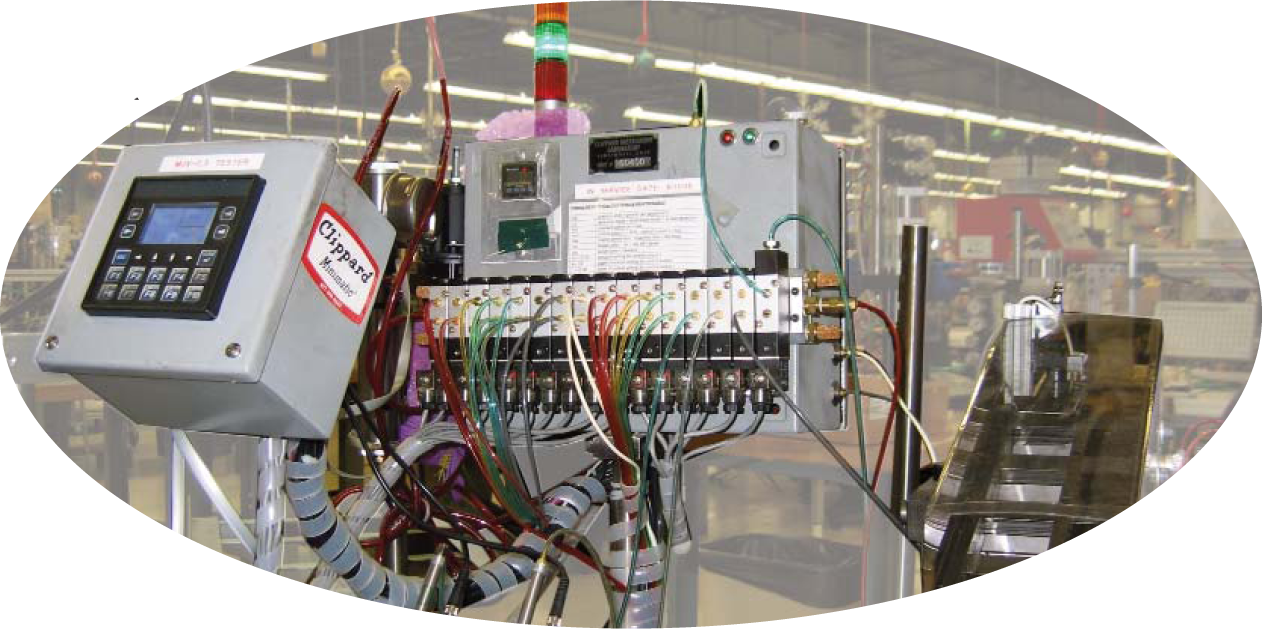

pressure decay technologyClippard utilizes pressure decay technology, and integrates automatic leak testing circuitry into our assembly equipment. We use our EV/ET, DV and EM series electronic valves to fill and hold pressure because they are bubble tight, do not generate heat, and have a billion cycle life expectancy. The Analytical Series has been designed specifically to reduce and limit potential leak paths within the valve. reliability & accuracyFor reliable, accurate leak test equipment designs, Clippard provides: Clippard’s miniature valves, actuators, fittings and regulators are ideal for these types of applications.

|

Clippard Two-Stage System Clippard Electronic Valves feature:• Billions of life cycles

Clippard has a long history of successfully partnering with progressive companies in the design and development of innovative pneumatic solutions for both portable and stationary leak detection equipment. How can Clippard’s engineering and application expertise assist in the development of efficient, compact pneumatic assemblies for your next leak test application?

|

||

|

|

|||